PeakSemi is a global supplier of power semiconductor modules and discretes. We provide affordable, high quality products used in various power electronic industries.

Mar 2020 - Discrete MOSFET Product Line Added

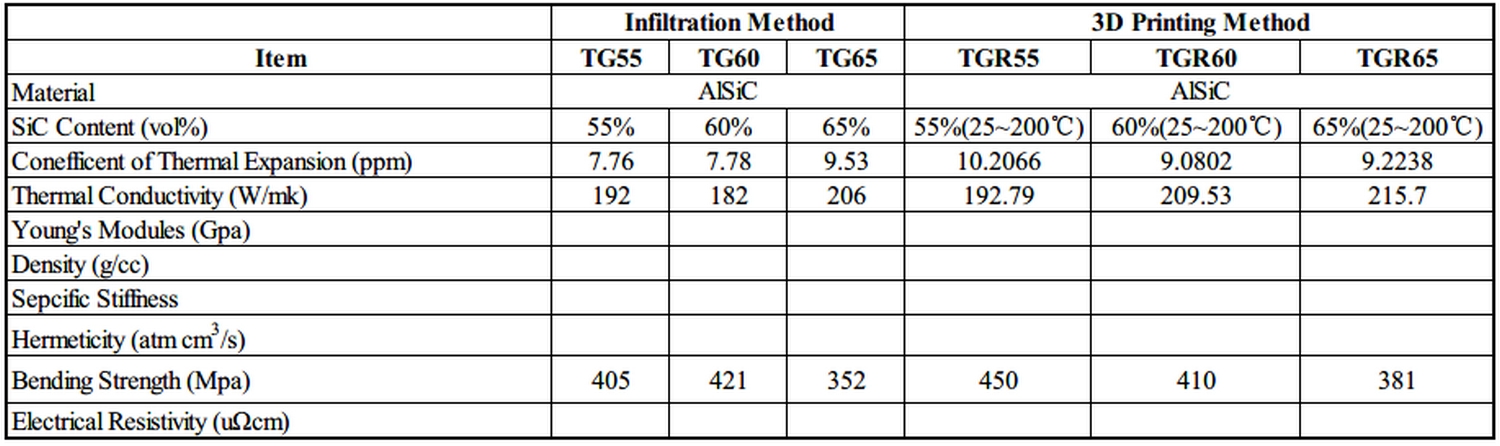

Peak Semi has been working with AlSiC OEMs to provide affordable AlSiC products. Two manufacturing methods are available for AlSiC production - traditional Infiltration and 3D printing. Peak Semi can provide products made with either method. The unique 3D printing process produces AlSiC products with low desity, high thermal conductivity, excellent CTE (Coefficient of Thermal Expansion) and exceptional mechanical properties.

3D printing technology in AlSiC manufacturing proivdes:

1. Increased part complexity

2. Reduced secondary processes, such as machining and lapping due to 3D printing's excelent surface finish.

3. Consistent Quality- Mixed powder can be easily tested and trial run before production to assure quality.

4. Short lead times - Comparing to the traditional manufacturing, lead time can be shortened up to 50%.

Traditional Infiltration provides:

1. Established, well known process.

2. Low cost Production for simple parts

3D Printing Information:

Max Component Size (L x W x H): 320 x 320 x 100 mm. Larger components can be built by brazing together subcomponents.